Multi Channel Flaw Detectors for Automatic Ultrasonic Testing

Advanced Platform / Core Component for the High Speed AUT

Machines and Process Monitoring Systems

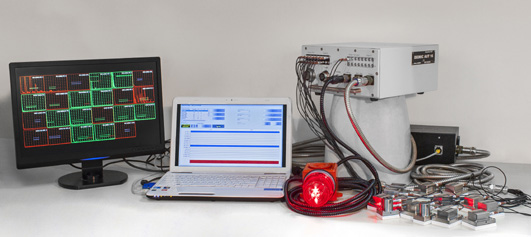

ISONIC AUT 16 / 32 are portable multi-channel instruments designed for servicing as the core components of high-speed automatic ultrasonic testing (AUT) machines and process monitoring systems

ISONIC AUT 16 / 32 comprises 16 / 32 identical independently adjustable channels. Each channel comprising pulser, receiver, and 100 MHz sampling rate signal digitizer (A/D Converter) has 2 probe terminals to drive either single or dual element probe or probe pair. The highest scanning speed is achieved through the parallel pulsing, receiving, digitizing, and recording of signals by all channels in use. However in the case of cross-talking through the material is possible the instrument’s channels may be toggled to work sequentially

Superior signal to noise ratio and dynamic range are achieved through firing probes with up to 400 Volt pp bi-polar square wave initial pulse. The duration and the amplitude of both positive and negative half-waves of the initial pulse are tuneable in the wide range. Further it is provided high stability of the firing amplitude selected by an operator within entire pulse width while the leading and falling edges of the bi-polar initial pulse are electronically boosted. Electronic damping circuit provides optimal amplitude / duration ratio for the received signals

Every channel is featured with 3 independent gates; beside regular functions the Gain per Gate Adjustment is possible for each gate – this allows implementing of pulse echo and back echo attenuation inspection techniques simultaneously, interface echo synchronizing, suppression of large geometry echoes, etc

ISONIC AUT 16/32 electronics is featured with:

- multi-axis encoder interface

- scanner motor control and powering interface

- interface for the external pedal and/or push-button “start/stop inspection” inputs

- user programmable lines for driving paint guns, audible alarm sirens, GO/NO-GO parts sorters, and the like

- user programmable proportional analogue outputs for the signal TOF / amplitude

The appropriate terminals are provided for any combination of the above external devices in accordance with the automation requirements

Scope of ultrasonic inspections performed by ISONIC AUT 16/32 includes multi-channel thickness gauging, pulse echo, pitch-catch, and through-transmission flaw detection, TOFD, and the like. The instruments are packed into the rugged portable light weight IP 67-sealed cases, which may be either fitted into the scanner’s chassis or mounted into a cabinet at the stationary inspection deck or just dropped onto the ground while in the field. A remote PC connected through LAN and appropriate inspection software package are required to control the instrument. The pre-scanning routine includes composing of multi-channel scanning strategy and automation logics followed by the calibrating of each channel involved. At the scanning stage the raw data comprising digitized ultrasonic signals and corresponding encoding information is streamed to the remote PC, which provides high-end processing, feedback to the instrument and external devices, imaging, logging, storage, etc. Fully digital control and data transfer allow practically unlimited distance between the instrument and remote PC enabling flexibility of creating control rooms or multiple monitor stations throughout the factory / hangar / weld station, etc |

|